Iso 16750-4 Ice Water Splash and Immersion Shock Test Chamber – Ice Water Thermal Shock Test Chamber

ISO 16750-4 Ice Water Shock Test Chamber mainly consists of two parts:

The upper part of the chamber functions as a hot air oven, capable of creating a uniform high-temperature environment up to 150 degrees Celsius within a short period. This section allows you to mount and remove samples easily through a front door equipped with a transparent viewing window.

The lower part consists of a water tank made from durable stainless steel to resist corrosion. Depending on your testing needs, you can fill the tank with a solution at high, medium, or low water levels. The powerful refrigeration system cools the solution down to ±2℃, maintaining this low temperature uniformly through water circulation cooling.

ISO 16750-4 ice water thermal shock test chamber main features:

- The outer shell is made of domestic high-quality steel plate CNC machine tools, and the surface is painted, which is beautiful and durable.

- All inner boxes are made of SUS316# stainless steel plate to ensure long-term rust-free.

- Insulation material: high-density glass fiber wool to ensure thermal insulation performance and keep the indoor temperature balanced and stable.

- A transparent observation window (multi-layer hollow tempered glass) is installed on the door, and an LED lighting lamp is installed on the door to facilitate observation of internal inspection conditions.

- High-quality fixed PU movable Korean casters are installed at the bottom of the machine, which can easily move the machine to the designated position.

- The control adopts 7-inch LCD touch screen control + PLC control, which can control the temperature in the box, water tank temperature, flow, water pump, and test time respectively; the flow and temperature are directly displayed on the touch screen, and the flow and temperature are automatically constant.

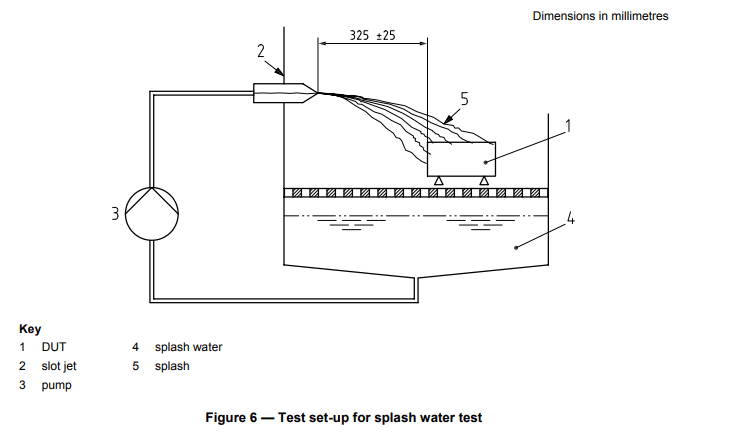

- Ice water splash test: the water spray peak is fixed on the right side of the test box; the water spray distance is adjusted by moving the sample.

- Flow meter: An electronic flow meter is used to measure the flow rate of the ice water splash test. The electronic flow meter signal is fed back to the PLC, and PID control is used to automatically control the constant flow. The flow rate is directly displayed on the touch screen.

- The ice water splash test uses a customized circulating water pump to ensure stable water flow and water temperature.

Technical parameters of ice water thermal shock test chamber:

| Structural parameters | |

| External dimensions | About 1500*deep 1900*high 2250 mm |

| Inner box size | About 1000*Inlet depth 1000*height 1000 mm |

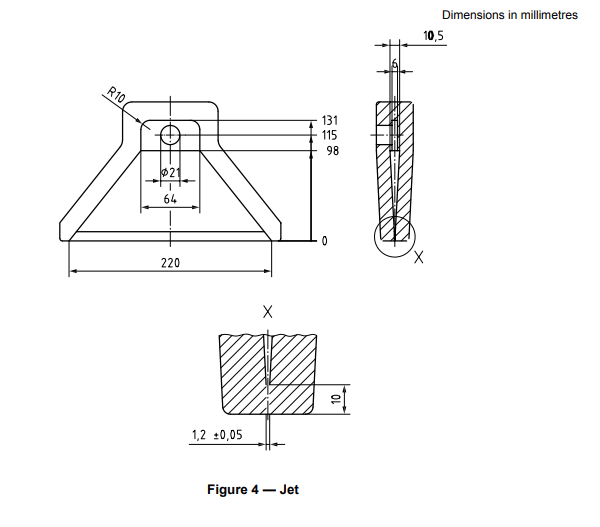

| Number of spray holes | 1 sewing spray torion; |

| Spraying position | On the right side of the inner box |

| distance between jet and DUT surface | 325 ± 25mm (manual adjustment) |

| Function parameters | |

| High temperature room temperature range | RT+10℃~150℃ |

| Heating rate | RT+10℃~150℃≤45min |

| Water temperature control range | (0~+4)℃ |

| Cooling rate | 25℃~2℃≤60min |

| water flow | between 3 L and 4 L per 3 s (splash duration); |

| Test liquid values | Remove water or+3%Arizona fine dust |

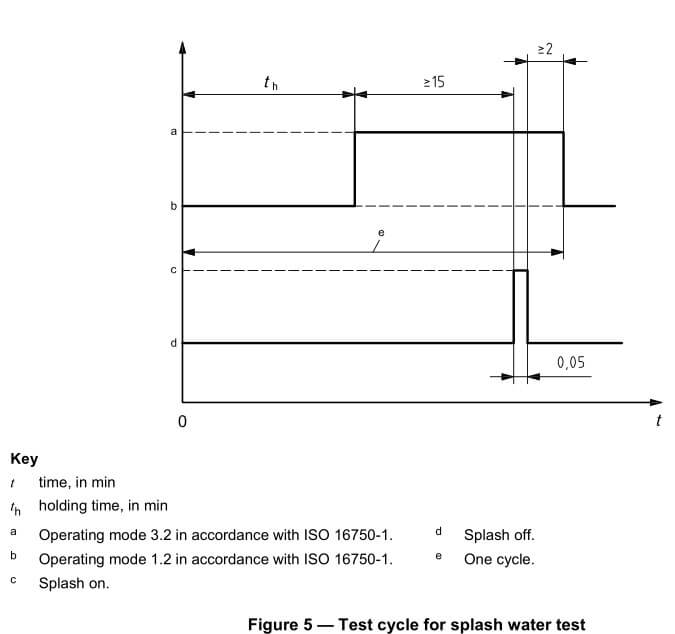

| Spray time per cycle (30 minutes) | 3s, interval time: interval time: 29m57s (touch screen setting) |

| Number of cycles | 100 times (touch screen setting) |

| Electrical parameter | |

| Device power supply | 380V/50Hz, three -phase and five -line system |

| equipment power | 12.0KW |

| Safety protection function | Leakage protection, water deficiency protection, short circuit protection, phase sequence protection, heat overload protection |