As technology progresses, the waterproof performance of various products has become a crucial evaluation criterion. Whether it’s automotive components, electronic devices, or outdoor equipment like cameras, superior waterproof performance is essential to ensure stable operation under harsh conditions. This necessity is met by advanced waterproof testing devices, with the IPX9K waterproof testing equipment being highly esteemed in the industry for its exceptional testing capabilities and extensive application range.

Overview of IPX9K Waterproof Testing Equipment

The IPX9K waterproof testing equipment is a high-precision, reliable device designed to simulate various high-pressure water impact scenarios that products might encounter in real-world environments. By subjecting products to prolonged, high-intensity water spray tests, this equipment can thoroughly and accurately evaluate their waterproof performance, aiding manufacturers in enhancing product design and quality.

Applications of IPX9K Waterproof Testing Equipment

Automotive Components

In the automotive sector, the IPX9K waterproof testing equipment is indispensable. Key car components such as engines, transmissions, and braking systems, along with external parts like headlights and windows, require excellent waterproof performance. Rigorous testing using IPX9K ensures these parts remain unaffected by water during rain or car washes, thereby improving vehicle safety and reliability.

Electronic Devices

Electronic devices also face significant challenges regarding waterproof performance. With the widespread use of portable gadgets like smartphones and tablets, consumers demand robust waterproof capabilities. The IPX9K waterproof testing equipment can perform comprehensive tests on these electronic products to ensure they remain functional and undamaged by water exposure during everyday use.

Outdoor Equipment

Outdoor products like cameras require even stricter waterproof standards due to their specific usage environments. Whether it’s surveillance cameras or action cameras, they need exceptional waterproof capabilities to withstand harsh weather conditions. The IPX9K equipment can simulate severe environmental water impacts to rigorously test these products, ensuring stable operation in any condition.

Other Industries

Beyond the aforementioned fields, the IPX9K waterproof testing equipment is widely used in medical devices, outdoor gear, aerospace, and other industries. For example, surgical instruments and outdoor backpacks must undergo stringent waterproof tests to guarantee their safety and reliability. The IPX9K equipment provides robust support for these industries with its excellent performance and broad application.

Advantages of BONAD’s BND-IPX9K High-Temperature and High-Pressure Waterproof Testing Chamber

BONAD’s BND-IPX9K high-temperature and high-pressure waterproof testing chamber offers unique advantages in the Chinese market:

Power Inverter Solutions

Different countries have varying voltage frequencies; for instance, the US uses a 220V three-phase 60Hz power supply while most Chinese manufacturers offer a 50Hz version converted from 380V to 220V. The IPX9K includes numerous components and motors that cannot operate on both 50Hz and 60Hz frequencies. Using a 50Hz version with a 60Hz power supply can cause motor overheating leading to damage and flow accuracy errors. BONAD’s product is specifically designed for 60Hz with most internal components being international brands like OMRON and Schneider for easy local replacement if issues arise over time.

Nozzle Design

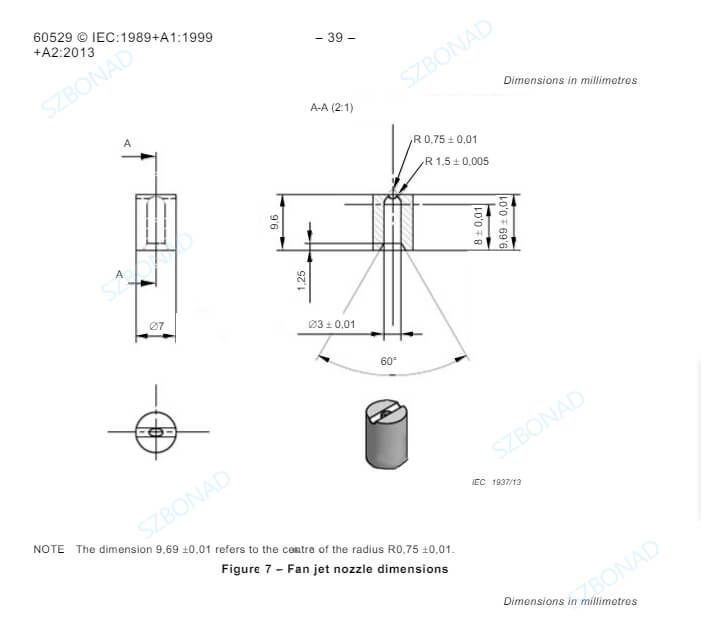

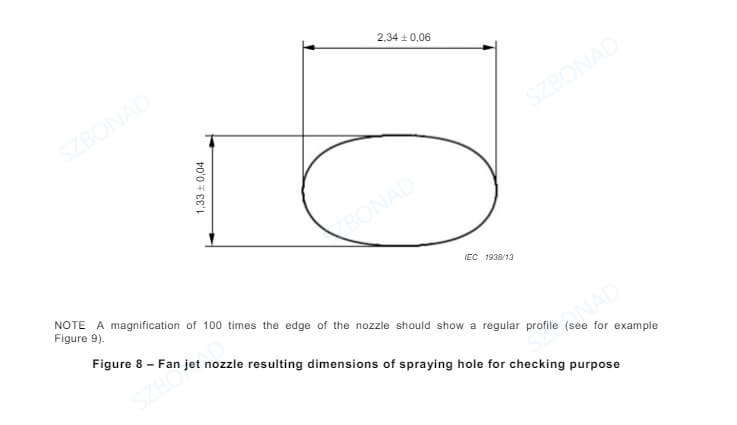

BONAD’s nozzle design fully complies with IEC60529 standards (Figures 7-12). Due to stringent dimensional requirements (see Figures 7-8 of IEC60529), no manufacturer in China can produce such nozzles. BONAD transports the nozzles to Japan for processing and has obtained a CNAS calibration certificate.

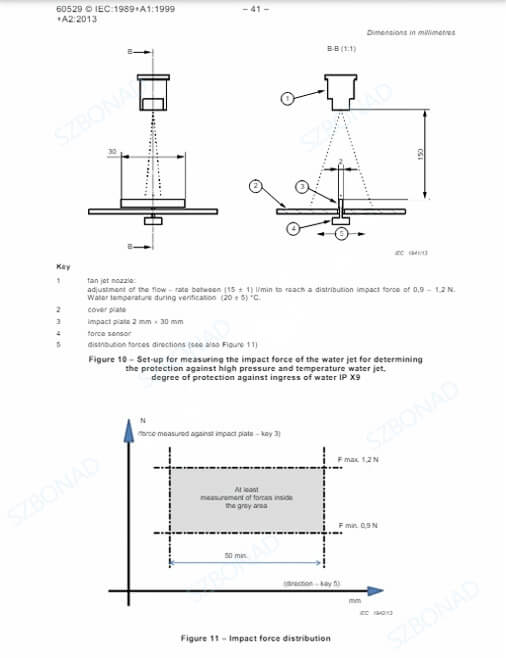

Most Chinese IPX9K manufacturers’ test chambers do not fully comply with IEC60529, DIN40050, and ISO20653 standards; some even lack force sensors (see Figure 10 of IEC60529). BONAD’s IPX9K equipment fully adheres to these international standards ensuring test accuracy and reliability.

Conclusion

The IPX9K waterproof testing equipment plays an essential role across various industries by helping manufacturers improve product design and quality through rigorous testing. BONAD’s BND-IPX9K high-temperature and high-pressure waterproof testing chamber further enhances this process with its superior design and strict standard compliance in the Chinese market.

Overall, the IPX9K waterproof testing equipment is vital for assessing the waterproof performance of automotive parts, electronic devices, and outdoor equipment like cameras. Through rigorous testing using this equipment, we can ensure these products exhibit outstanding waterproof performance allowing them to operate reliably in diverse harsh environments. With ongoing technological advancements and expanding application fields, the role of IPX9K waterproof testing equipment is expected to grow even more significant in the future bringing increased convenience and safety to our lives.