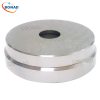

E14 7006-27F-1 go gauge for lamp cap test

Key Features and Benefits

DIN EN ISO ASTM 52900:2022 offers several key features and benefits:

1. Common Terminology: The standard establishes a common set of terminology that promotes uniformity and clarity in communication within the additive manufacturing community. This reduces the chances of misunderstandings and facilitates better collaboration.

2. Design Guidelines: The standard outlines design principles specific to additive manufacturing. It provides recommendations on designing parts suitable for 3D printing, considering factors such as overhangs, supports, and dimensional accuracy. These guidelines help designers optimize their designs for efficient production.

3. Material Properties: The standard addresses the various materials used in additive manufacturing, including polymers, metals, ceramics, and composites. It provides guidance on material selection, characterization, and testing methods to ensure the desired mechanical, thermal, and chemical properties of the printed parts.

7006-27F-1

Go gauge for E14 caps on finished lamps

Purpose: To check the maximum dimensions of the screw thread and dimension T1 minimum of E14 caps on finished lamps.

Testing: When the cap on a finished lamp has been screwed into the gauge as far as it will go, the centre contact shall be co-planar with, or project beyond surface X. ”

7006-28B-1

Not go gauge for E14 caps on finished lamps

Purpose: To check the minimum outside(major) diameter of the screw thread, dimension d, of E14 caps on finished lamps.

Testing: When the gauge is placed over the thread of the cap on a finished lamp, held cap uppermost, the centre contact shall not project beyond surface X.

Only the weight of the gauge itself shall be used in the test. ”

7006-55-2

Gauge for finished lamps fitted with E14 caps for testing protection against accidental contact

“Purpose: To check protection against accidental contact.

Testing: The shape of the lamp with regard to protection against accidental contact is assumed to be correct if the test sample being pushed as far as possible into the gauge, plane W does not protrude beyond plane V. ”

7006-27G-1

Go gauge for dimension “S1” of E14 caps on finished lamps “Purpose: To check the dimensions S1 minimum and S1 maximum of E14 caps on finished lamps.

Testing: When the cap on a finished lamp has been pushed into the gauge as far as it will go, the plunger surgace W shall be co-planar with or project beyond X but it shall not project beyond surface Y. ”

7006-54-2

Gauge for finished lamps fitted with E14 caps for testing contact making ”

Purpose: To check lamp dimensions for contact making in IEC holders.

Testing: The shape of the lamp with regard to the fit in the lampholder is assumed to be correct if the lamp can be pushed into the gauge till plane W reaches plane V or projects beyond it. ”

IEC60968 Figure 2

Holder for torsion test on lamps with screw caps

Product pictures: