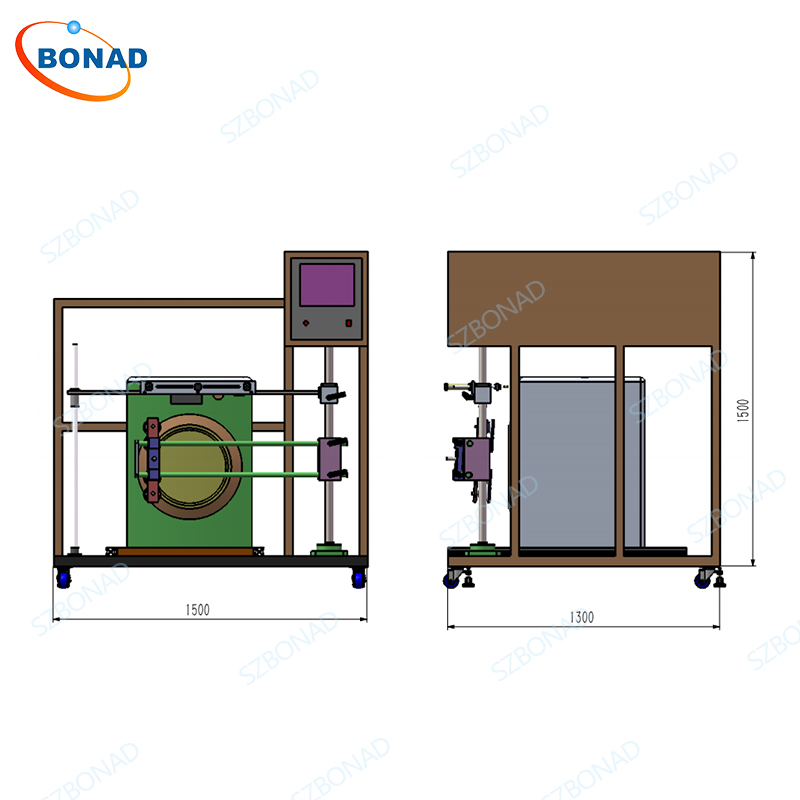

IEC60335 PLC Control Touch Screen Washing Machine Door Durability Tester

The test equipment uses the most advanced PLC touch screen control plus stepper motor (or servo motor, which can be customized according to needs), which can preset the test angle and speed, truly simulate the opening and closing of the washing machine door, and realize intelligent control.

Standard:

1. IEC 60335-2-4 clause 18

2. IEC 60335-2-7 clause 18,clause 22.104

3. IEC 60335-2-11 clause 20.101

Application:

It is used to test the durability of the interlocking device of the washing machine door or cover, and the force test when the interlocking device is in action to verify the reliability of the interlocking device; it is also used to assist other tests of repeated opening and closing operations of the washing machine door or cover.

Features:

1. Washing machine door durability test equipment adopts PLC intelligent control system, and the touch screen humanized operation interface can record and display test data.

2. The load output of the tested sample is adjustable and displayed.

3. The number of tests, test speed, test stroke, door opening/closing force, etc. can be preset and displayed in real time on the touch screen.

Test principle:

By formulating a program to control the opening and closing action of the interlocking device, the servo motor drives the manipulator to reciprocate and open and close the door or cover at a certain speed, and the vacuum suction cup is adsorbed on the door or the clamp clamps the cover, thereby verifying the reliability of the interlocking device. A force sensor is installed on the manipulator to form a closed-loop control with the servo motor to accurately control the opening and closing force value of the door or cover.

Technical parameters:

| Feature | Description |

|---|---|

| Test Station | 1 station (top-opening and side-opening) for independent testing |

| Opening/Closing Speed | 5-25 times/minute, adjustable |

| Sample Size | 100 * 100 * 130 cm (customizable per user requirements) |

| Top-Hinged Door Opening Angle | 45°, 90°, 120° adjustable |

| Bottom-Hinged Door Opening Angle | 0-90° adjustable |

| Mechanism for Fixing Robot and Door | Vacuum suction cups |

| Connection Between Suction Cup and Robotic Arm | Lightweight sliding connection |

| Conversion of Left and Right Doors | Adjust by changing the direction of suction cup and robotic arm output axis |

| Lifting Height of Sample Table at Bottom-Hinged Door Station | Above table surface: 100 mm, Below table surface: 400 mm |

| Testing Fixtures | 2 sets (one set for top-opening washing machine, one set for front-opening washing machine) |

| Door State Detection | Photoelectric sensor |

| Control of Force Applied to Open Machine Doors or Covers | 50N – 200N, using stepper motor (or servo motor), adjusts torque by setting motor pulse signals to control opening force |

| Test Count | 0-999999 (adjustable) |

| Drive Method | Servo motor |

| Control Method | Touch screen + PLC control, adjustable test rate, actions, stop time, test count, test angles, etc. |

| Frame Material | Aluminum alloy frame structure |

| Power Supply | AC220V ±10%, 50-60Hz |

| Air Supply | 0.7 Mpa |