Battery Fire Resistance Combustion Test Machine – Battery Fire Test Device

The combustion test chamber is divided into inner and outer layers. The inner box is made of SUS304 stainless steel plate, and the outer box is made of cold-rolled steel plate. The size and thickness of the box can be customized according to your test samples and requirements. The test chamber is equipped with lighting inside, and a transparent window made of double-layer tempered glass with a size of 250x250mm can be used to clearly observe the experimental status. At the same time, the test chamber is equipped with a smoke exhaust system, a pressure relief system, and an ignition controller, which can safely and conveniently perform battery combustion tests.

Battery flammability test:

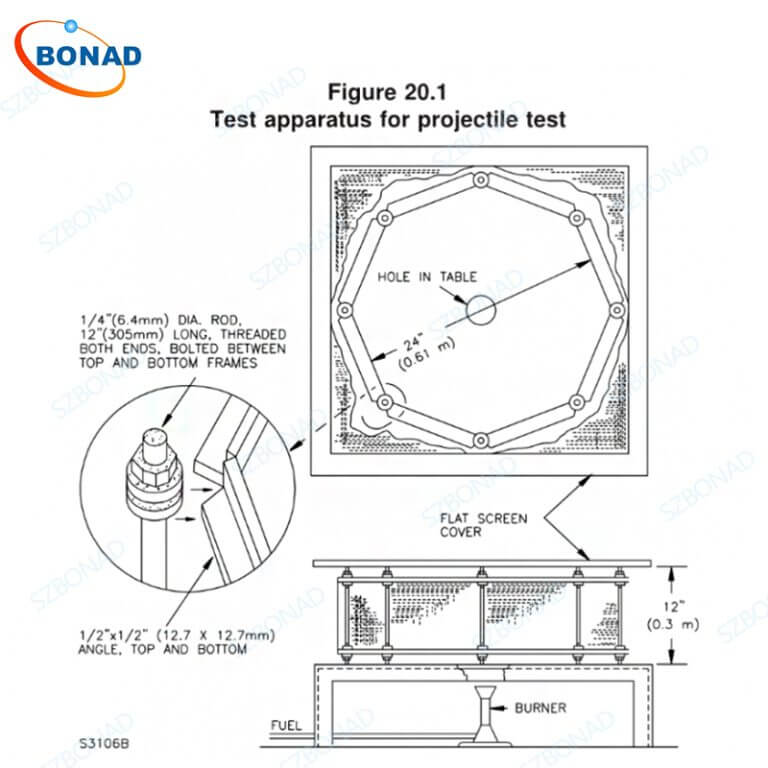

A circular hole with a diameter of 102 mm is drilled on the experimental platform. A wire mesh is placed on the circular hole and the battery to be tested is placed on the wire mesh. An octagonal aluminum mesh is installed around the pattern. The burner is lit to heat the sample until the battery explodes or burns.

Test standards:

- UL 1642 Lithium Battery Standard.

- UL 2054 Household and Commercial Battery Packs.

- UL 2271 Batteries for Light Electric Vehicles.

- 3 Recommendations on the Transport of Dangerous Goods – Manual of Tests and Criteria – Part 3.

- IEC62133 Safety Requirements for Batteries and Batteries Containing Alkaline or Non-acidic Electrolytes.

- IEC 62281 Safety Requirements for Lithium Primary Cells and Batteries in Transport.

- IEC 60086 Primary Cells Part 4 Safety Requirements for Lithium Batteries.

Technical parameters:

| Control method | PLC+Touch screen control |

| Inner box size | 730x740x600mm(Widthxdeepxhigh)(Size can be customized according to customer’s requirements, price is negotiable) |

| Dimensions | 870x1000x1400mm(Widthxdeepxhigh) |

| Inner box material | SUS304 stainless steel plate, thickness 1.2mm, inner box can be pasted with Teflon tape (Optional) |

| Outer box material | 1.5mm thick cold rolled steel plate with paint treatment |

| Observation window | Size is 250x250mm double-layer tempered glass, transparent window is equipped with stainless steel mesh |

| Lighting | The machine is equipped with a lighting lamp to facilitate observation of the status of the tested sample. |

| Smoke outlet | The diameter is 100mm and is located at the back of the box. There is also an exhaust fan in the box. |

| Pressure relief port | The opening size is 200x200mm, located at the back of the box. When the sample explodes, the pressure relief port pops open to release the pressure. |

| Door | The single door opens to the left, and an explosion-proof chain is installed on the side of the door to ensure personnel safety |

| Control method | Touch screen control |

| Burner | Bunsen burner, with an inner diameter of 9.5 mm and a length of about 100 mm |

| Flame application time | 0~999.9 seconds±0.1 seconds |

| Burning time | 0-99H, H/M/S units can be switched |

| Ignition controller | Remote control ignition, automatic control of the test process (This item is optional) |

| Remote control distance | No obstruction, 10 meters (This item is optional) |

| Test hole diameter | 100±2mm |

| Test mesh sieve | A wire mesh woven from stainless steel wire with a diameter of 0.45 mm (0.017 inch), with a mesh size of 20 meshes per inch. |

| Height from flame to screen | 38mm |

| Octagonal grille width | The parallel distance between opposite sides is 610mm (24″), octagonal, eight sides are movable, easy to replace and disassemble |

| Octagonal grille height | 305mm (12″) |

| Octagonal cover material | Aluminum mesh material, the specification of aluminum wire mesh is woven from aluminum wire with a diameter of 0.25mm (0.010inch). A mesh composition containing 16-18 grids per inch (mesh number 16-18). |

| Combustion gas | Methane or LPG(To be prepared by the customer) |

| Equipment weight | 160kg |

| power supply | AC220V |

| power | 800W |