Manual Booster Pump For Chemical Battery Case Pressure Testing Of Monolithic Cells – BONAD Test Equipment

Standards:

Our booster pump meets international safety standards including:

- IEC 62133: Ensuring safety requirements for portable sealed secondary cells and batteries.

- UL 1642: Complying with lithium battery standards.

- UN 38.3: Adhering to test requirements for lithium battery transportation as per the United Nations guidelines.

Applications:

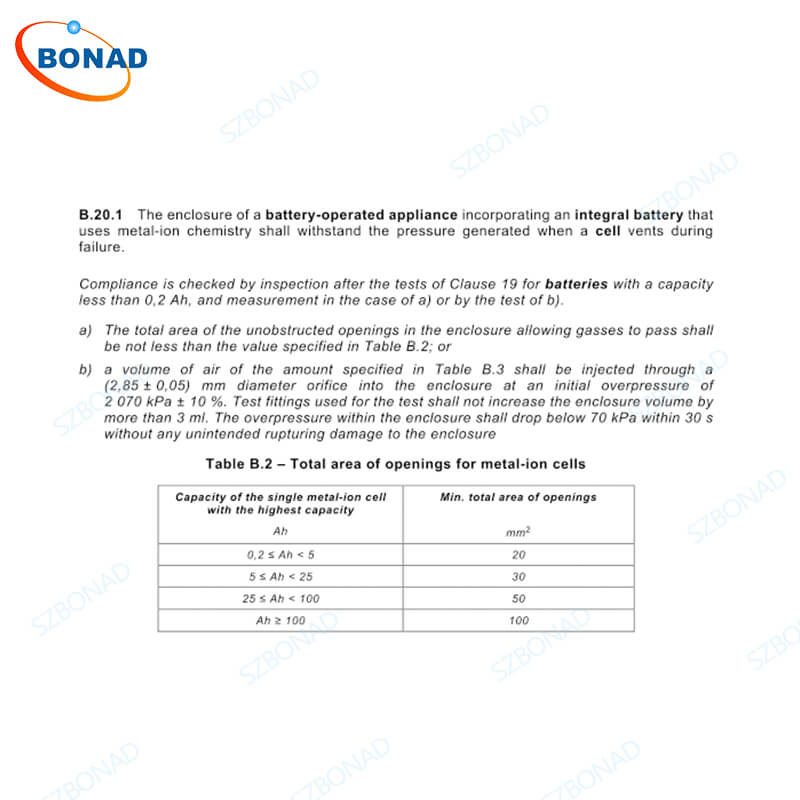

This manual pump is ideal for measuring the pressure generated by a battery during failure scenarios in devices powered by monolithic metal ion chemistry batteries. It helps verify the strength of the battery casing under stress conditions.

Features:

- High-Precision Pressure Control: Equipped with high-precision gauges and regulators to meet various testing needs.

- Wide Pressure Range: Typically ranges from 0 to 2.5MPa but can be customized according to specific requirements.

- Manual Operation: No power supply needed; operations like pressurization and pressure relief are manually controlled.

- Safety Assurance: Includes a safety valve that automatically releases excess pressure.

- Portable Design: Compact and lightweight for easy transport.

- Durability: Constructed from high-quality materials to ensure long-lasting performance.

Testing capabilities:

The Manual Booster Pump facilitates several critical tests:

- Battery Shell Pressure Test: Evaluates deformation or rupture under internal pressure.

- Battery Sealing Performance Test: Assesses sealing integrity to prevent electrolyte leakage.

- Battery Safety Performance Test: Simulates internal gas generation to test safety valve performance.

Technical parameters:

| Parameter | Specification |

|---|---|

| Test Station | 1 Station |

| Control Method | Manual control, button operation |

| Driving Mode | Manual booster pump drive |

| Testing Medium | Gas |

| Test Pressure | 0.01-2.5 MPa, monitored by pressure sensor |

| Gas Capacity | 20, 30, 50, 100 ml (optional) |

| Test Time | Adjustable from 0 to 999999 |

| Sealing Joint | Standard set, opening φ2.85±0.05 mm |

| Testing Process | Manual loading and unloading test, automated detection process |

| Operating Environment | Atmospheric pressure 80–106 kPa; ambient temperature 5–40℃; relative humidity (20–80)% RH; usage location: no severe shaking, vibration, electromagnetic interference; dust-free; no explosive or corrosive gases; good heat dissipation |

| Equipment Dimensions | Approximately 700 × 500 × 500 (mm) W × H × D |

| Equipment Weight | 100 kg |

| Power Supply | AC220V ±10% / 50-60 Hz; operating environment: working temperature 0-40℃; humidity 30%-90% |