IEC 60335-2-2 Vacuum Cleaner Current-Carrying Hoses Abrasion Resistance Test Equipment

Standard

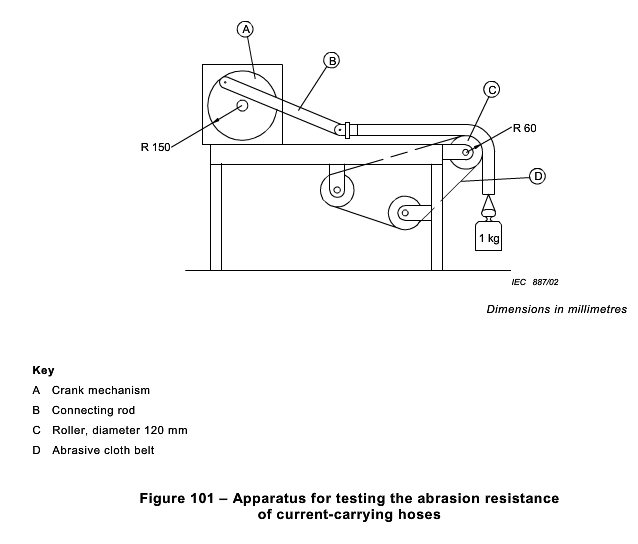

The tester complies with IEC60335-2-2 Clause 21.102 figure 101, ensuring reliable and standardized testing results.

Main Technical Parameters

| Feature | Description |

|---|---|

| Control Mode | PLC control with a touch screen human-machine interface for intelligent operation. |

| Test Station | Single station. |

| Frame Structure | Made from electrophoretic aluminum alloy with sprayed steel plate sealing; left-right structure, with control part on the left and test operation table on the right. |

| Tester Drive | Stepper reduction motor. |

| Crank Speed | Adjustable up to 30RPM via touch screen settings. |

| Moving Distance | 300mm. |

| Moving Speed | Adjustable to 0.1m/mm via touch screen settings. |

| Test Belt | Complies with ISO/DIS6344 P100 size requirements. |

| Weight | 1Kg. |

| Center Distance | The weight is positioned 600mm from the roller center. |

| Installation Position | The support plate should be pulled out during installation, with the weight placed on it and connected to the sample at exactly 600mm from the roller center. |

| Number of Tests | Configurable between 0-999 times via touch screen settings. |

| Equipment Power Supply | AC220V 50Hz. |

Test Procedure (Excerpted from IEC60335-2-2 Clause 21.102)

- Connect one end of the hose to the crank mechanism’s connecting rod as shown in Figure 101. The crank rotates at a speed of 30 RPM, causing horizontal back-and-forth movement within a distance of 300 mm.

- Support the hose with a rotating smooth roller covered by an abrasive cloth belt moving at a speed of 0.1 m/min. Use corundum particle size P100 abrasive as per ISO6344-2 standards, and hang a 1 kg weight at the other end of the hose while guiding it to prevent rotation.

- Conduct the test for 100 rotations, ensuring that basic insulation is not exposed post-test, followed by an electrical strength test as per clause 16.3 between connected conductors and saline solution.

Maintenance Notes

- Cleaning: Keep the machine clean at all times to ensure optimal performance.

- Rust Prevention: Regularly spray anti-rust oil on metal parts and standard interchangeable parts after use.

- Lubrication: Periodically add lubricating oil to all rotating parts of the machine.