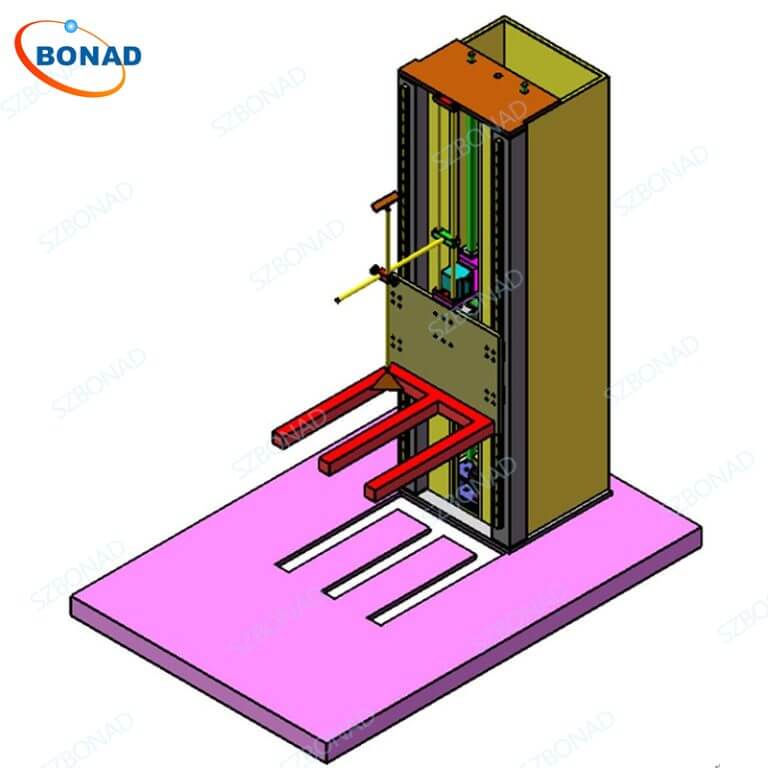

Simulated Packaging Zero Distance Drop Test Machine – Large Packaging Drop Test Equipment

The zero drop test machine is composed of an “E”-shaped fork that can move downward quickly as the specimen holder, and the test goods are placed and balanced according to the test requirements (face, edge, and corner test). During the test, the pallet moves downward at high speed and detaches from the test piece. Before the test packaged goods fall to the bottom plate, the “E”-shaped fork has been embedded in the bottom plate under the action of the high-efficiency shock absorber. In theory, the zero drop test machine can perform drop tests from zero height to the maximum drop height. The drop height is digitally set according to the test requirements, and the drop test is automatically performed according to the set height.

Test standards:

- ISO 2248

- ASTM D5276

- JIS Z 0200

- JIS Z 0202

Zero distance drop tester features:

- This zero-distance drop tester is suitable for large-scale package drop test.

- The maximum drop height error is 10mm.

- The drop height is 0-1500mm, which can be freely adjusted according to the test requirements.

- Equipped with E-shaped “fork” and auxiliary devices, the test package can be impacted on the edge, corner or surface.

- PLC touch screen control + remote control, the test is more accurate.

- Upper and lower limiter protection makes the test safer.

- The electric motor adopts double guide rails to ensure smooth and reliable lifting process.

- The cylinder realizes reset and drop, and the air pressure is automatically interlocked to prevent the swing arm from abnormally disengaging due to loss of air pressure.

- The impact plate is made of 45# steel, solid steel plate, which is more solid and safe.

Technical parameters:

| Equipment Specifications | 1500mm, 60Kg |

| Drop height | 0~1500mm (adjustable, configurable) |

| Drop height error | ±10mm (1%) |

| Maximum load | 60Kg |

| Maximum specimen size | 1660×430×1100 (mm) |

| Drop test method | Free fall drop test |

| Testing | Implement surface, edge and corner drop tests |

| Impact base plate effective size | 1800×1200 (mm) |

| Impact plate material | 45# steel, solid steel plate |

| Control method | PLC touch screen control + remote control |

| Equipment lifting method | Electric (motor), with double guide rails, the lifting process is smooth and reliable |

| Support arm power | Pneumatic |

| Equipment dimensions: approx. | 2000×1400×2300mm |

| Equipment weight approx. | 2000Kg |

| Protective devices | Upper and lower limiter protection |

| Using Power | AC 380V 50/60HZ |

| Total power approx. | 3.5KW |

| Gas source | Air compressor |