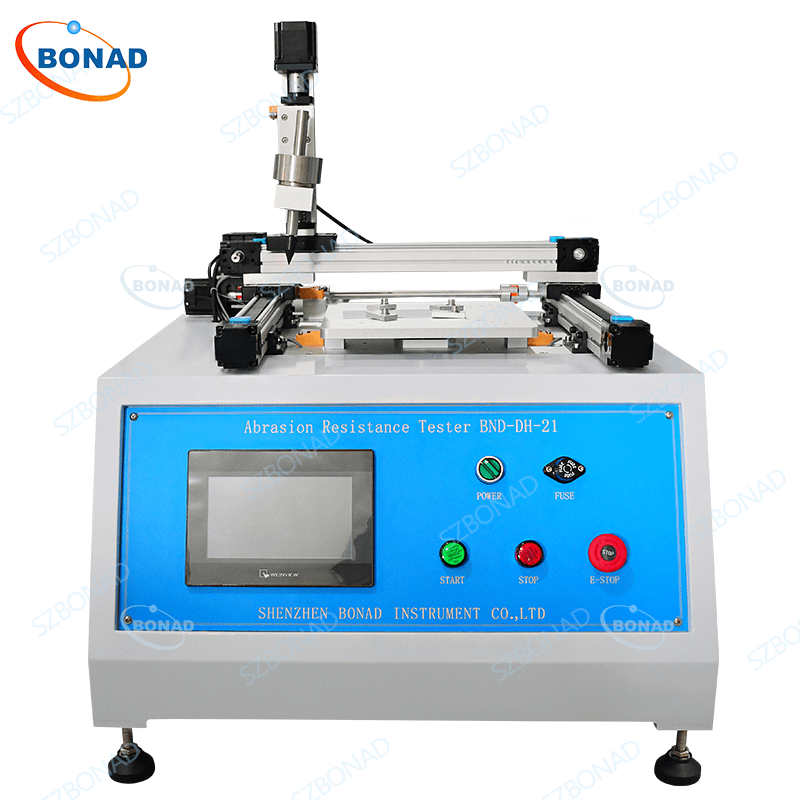

Scratch Resistance Test Machine – High Quality Wear Resistance Testing Machine

The scratch resistance test machine mainly evaluates the ability of the material to resist scratches by simulating the scratches on the surface of the material in the actual use environment. The test machine uses a needle-shaped or spherical indenter with high hardness to perform a scratch test on the material surface under a certain load and speed. During the test, the scratch resistance test machine records the parameters such as the depth, width and shape of the scratches, and evaluates the scratch resistance of the material based on these data.

Scratch resistance testing machine features:

- High-precision measurement: The scratch tester uses high-precision sensors and control systems, which can accurately measure the depth, width and length of scratches to ensure the accuracy and reliability of the test results.

- Strong versatility: The equipment is suitable for scratch testing of various materials, such as coatings, paints, plastics, rubber, etc. At the same time, by adjusting parameters such as the movement speed and stroke of the stylus, the test requirements of different materials can be met.

- Easy operation: The scratch tester adopts an electric drive mode, which is simple and convenient to operate. During the test, just place the sample on the equipment workbench, adjust the movement parameters of the stylus, and start the test.

- Strong data processing capabilities: The equipment is equipped with professional computer software, which can automatically record, analyze and process the test data and generate detailed test reports.

Technical Parameters:

| Input power supply | AC 220V/50Hz |

| Test station | One station |

| Control system | PLC + touch screen |

| Drive mode | Stepper motor drive |

| Scratching speed | 0-25mm/s adjustable, can be preset |

| Scratching times | 0-9999 times, it can be preset |

| Scratching distance | Approximately 25 % of the length of the insulation, can be preset |

| Test bench | Can be 90° rotated |

| Scratching pressure | 10N±0.5N |

| Scratching pin | hardened steel pin, the end of which has the form of a cone with an angle of 40°. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm |

| Scratching angle | 80° to 85° to the horizontal |

| Input power supply | AC 220V/50Hz |

| Test station | One station |

| Control system | PLC + touch screen |

| Drive mode | Stepper motor drive |

| Scratching speed | 0-25mm/s adjustable, can be preset |

| Scratching times | 0-9999 times, it can be preset |

| Scratching distance | Approximately 25 % of the length of the insulation, can be preset |

| Test bench | Can be 90° rotated |

| Scratching pressure | 10N±0.5N |

| Scratching pin | hardened steel pin, the end of which has the form of a cone with an angle of 40°. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm |

| Scratching angle | 80° to 85° to the horizontal |