Glow Wire Flammability Index Laboratory Test Principle:

The glow wire tester heats the heating wire (Φ4 mm nickel-chromium wire) of specified material (Ni80/Cr20) and shape to the test temperature (550℃~960℃ for 1min) with a large current, and then vertically burns the test sample with a specified pressure (1.0N) for 30s. The fire hazard of finished electrical and electronic equipment is determined by whether the test sample and the bedding ignite or the burning time; the ignition property, ignition temperature (GWIT), flammability and flammability index (GWFI) of solid insulating materials and other solid combustible materials are determined.

Glow Wire Test Chamber Application:

The glow wire test chamber is suitable for the research, production and quality inspection departments of lighting equipment, low-voltage electrical appliances, electrical instruments, and other electrical and electronic products and their components.

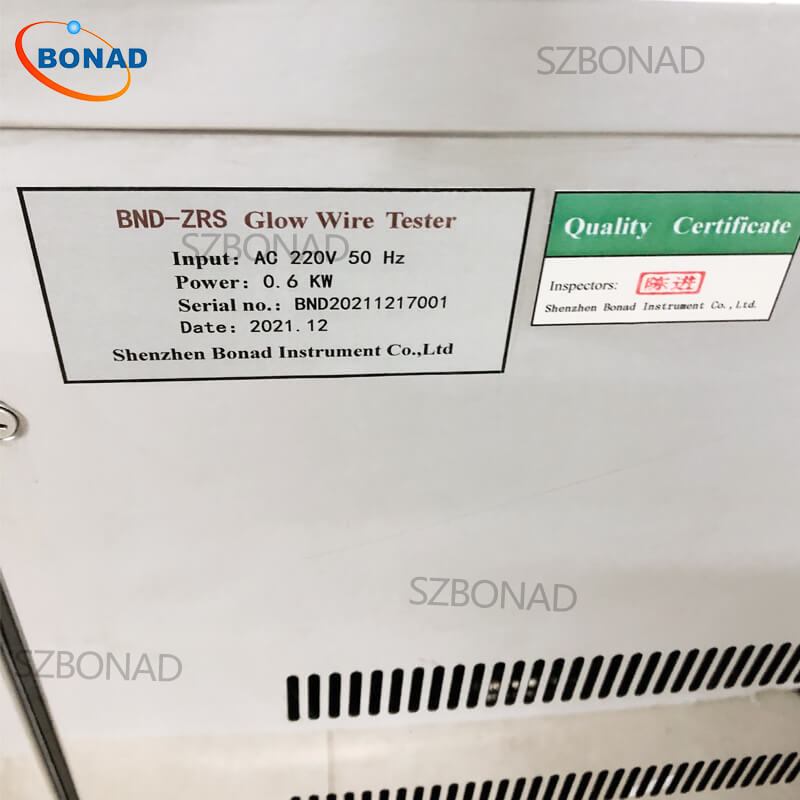

Glow Wire Test Chamber Technical Parameters:

| Glow wire temperature | 500 ~ 1000 ℃ ± 2 ℃adjustable |

| Heating time | 0-999.9s ± 0.1s,adjustable (normally choose to 30s) |

| Ignition timer | 0-999.9s ± 0.1s, automatically records, manually suspended |

| Thermocouple | Φ0.5mm sheathed K-type thermocouple. |

| Flame extinguish time | 0-999.9s ± 0.1s, automatically records, manually suspended |

| Glow wire | Φ4 mm nickel chromium wire. |

| hot depth | 7mm ± 0.5mm (to maintain the pressure of 1N ± 0.2N hot products into the test) |

| Sample frame speed | about 14mm / s |

| the pilot background | black background. |

| the pilot process | automatic testing procedures, independent ventilation |

| reference | IEC60695-2-10, UL746A,GB/T5169.10-2006 |

| Studio volume | 0.5 cubic |

| equipment size | 1000mm wide × 650mm deep × 1300mm high |

| power supply | AC220V ± 5%, 50Hz, 0.6KVA |